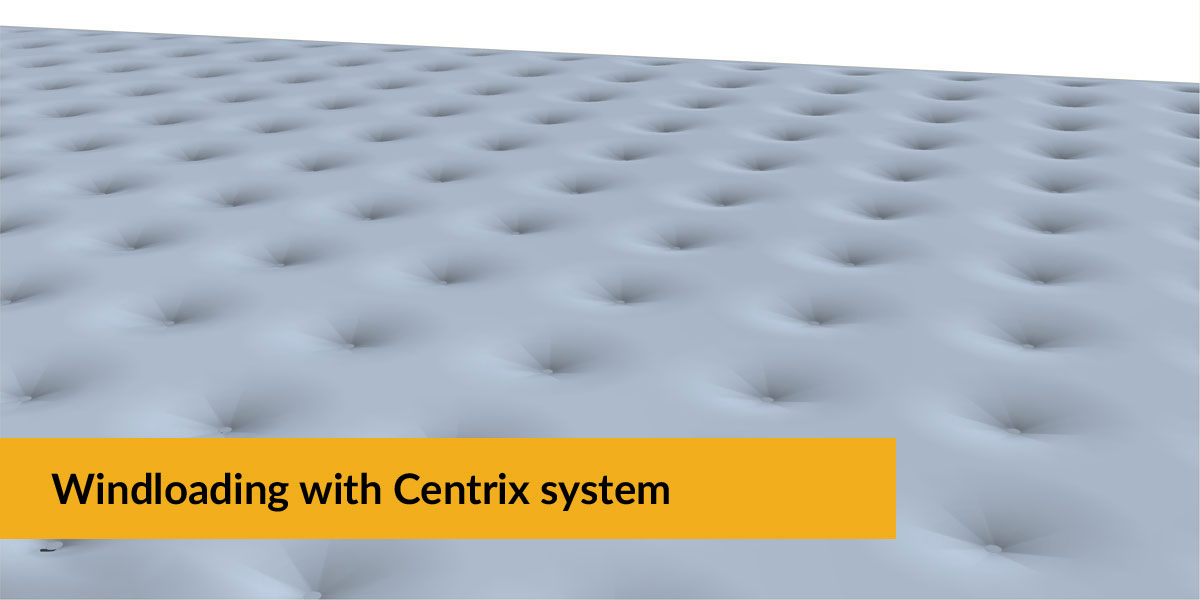

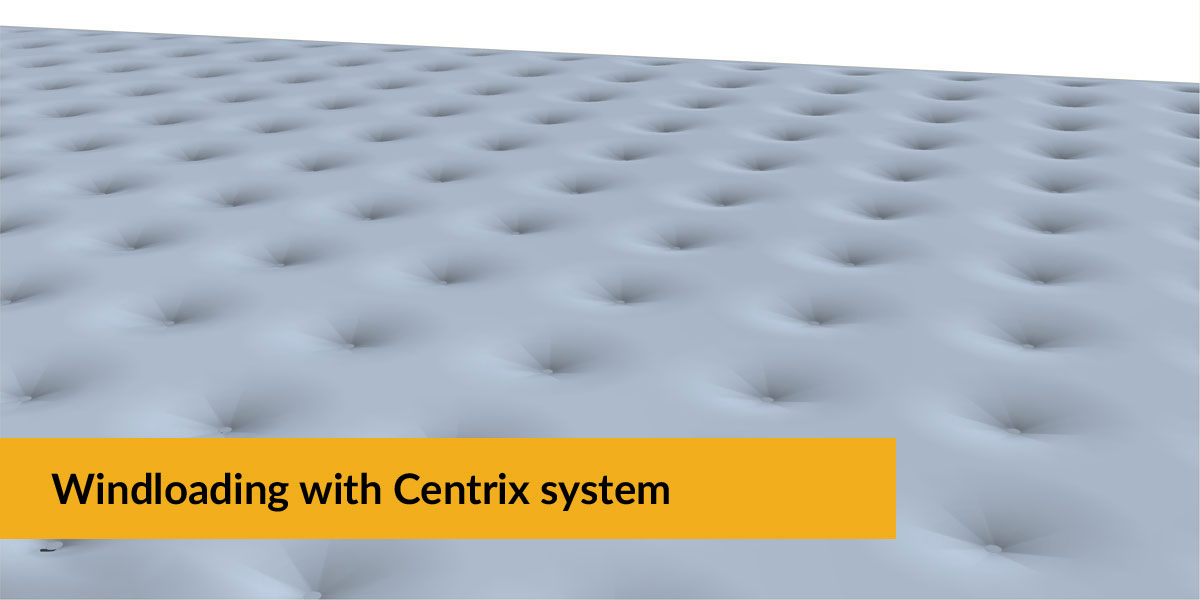

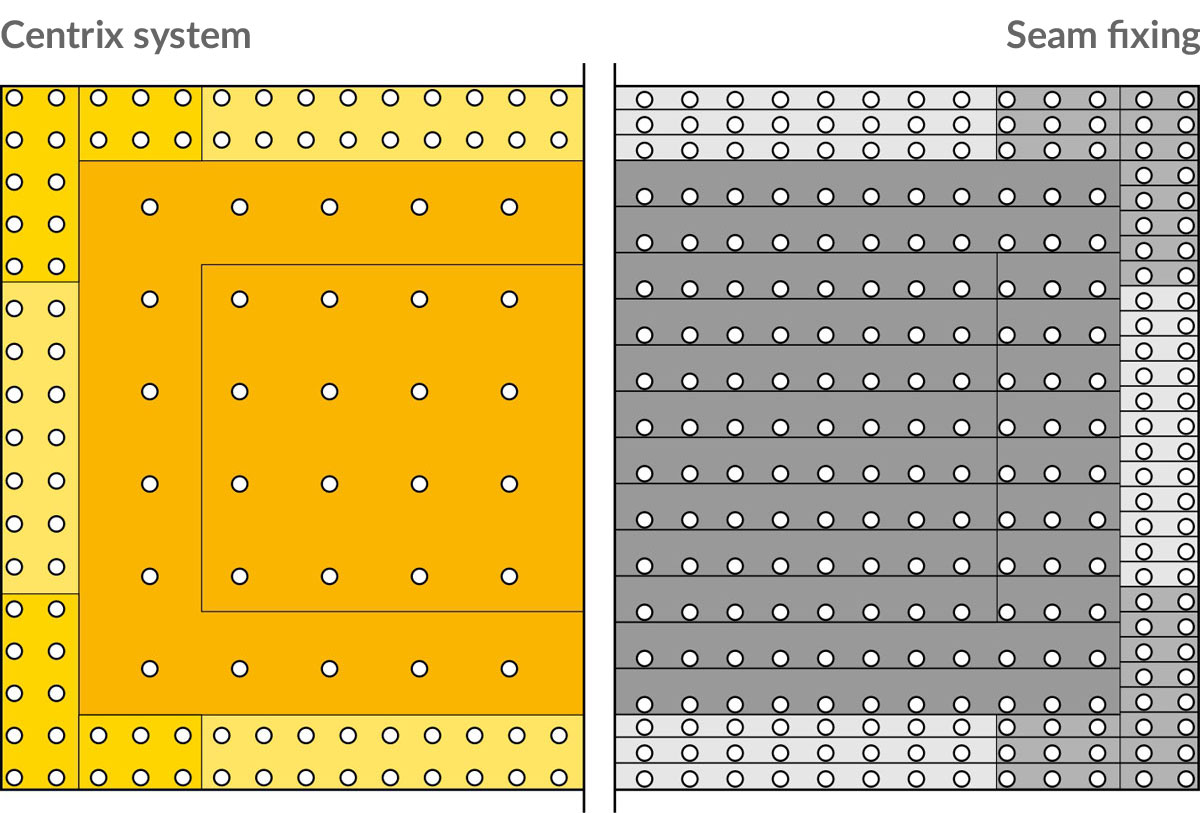

Even fastener distribution balances wind load and prevents roof flutter

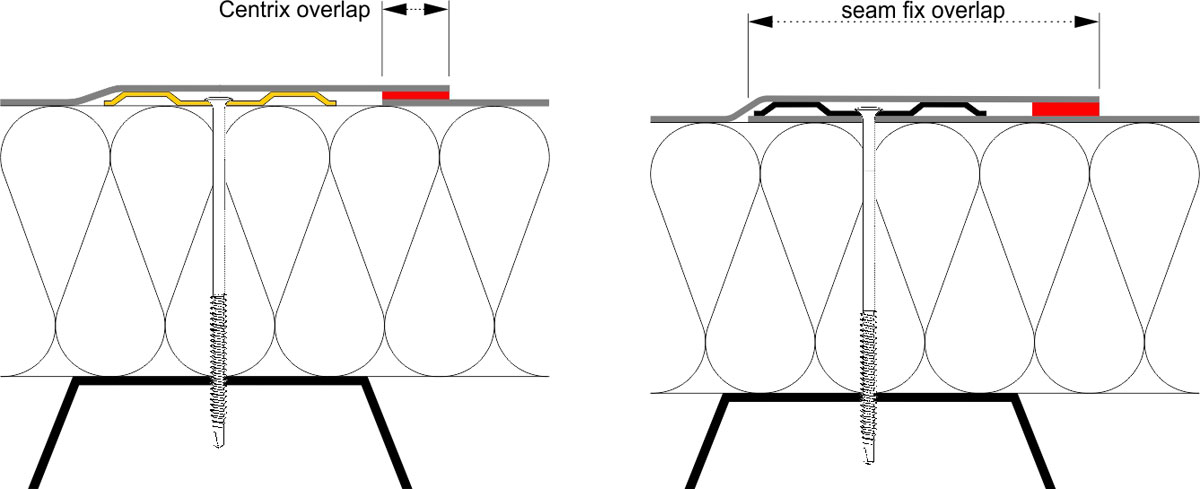

Where traditional methods force you to fix the membrane along the seams – causing the membrane to billow in high winds – Centrix lets you position the fasteners in an even pattern. This balances wind-load distribution, keeping any billowing to a minimum and preventing membrane flutter. Which reduces membrane fatigue and fastener loading, enhancing long-term performance.

Superior wind uplift resistance

Thanks to the even fastener pattern you can create with Centrix – and thanks to the sheer strength of our bond to the membrane – you can achieve outstanding wind uplift performance, with fewer fasteners than with seam fixing.

Fewer fasteners mean less thermal bridging and reduced risk of corrosion failure

Requiring a smaller number of fixings than traditional methods, the Centrix system causes less heat to be lost through the roof. And, as well as this thermal efficiency, fewer metal parts means less chance of corrosion problems.

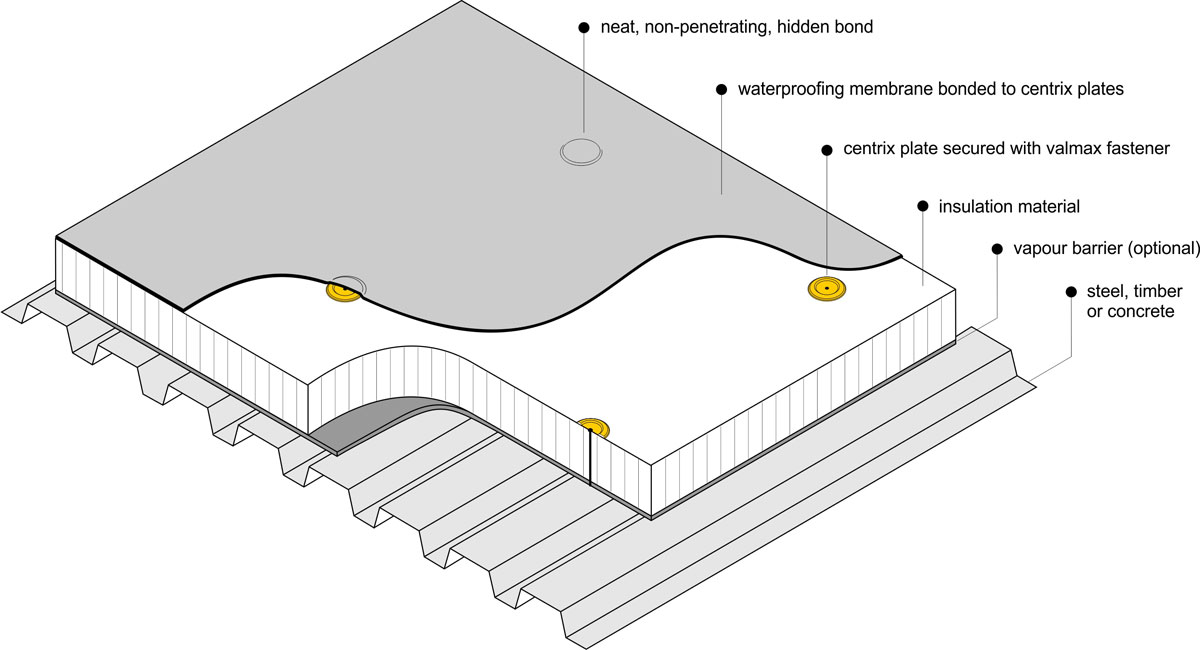

Non-penetrating system prevents weaknesses and leaks, and improves appearance

With Centrix, no fixings pierce the membrane, so you avoid any related risks of weakening the material or creating leaks. Also, because our system uses wide membrane and hidden bonded fasteners, you remove the need for messy joins and overlaps in the membrane, giving a tidy, smooth-looking roof.

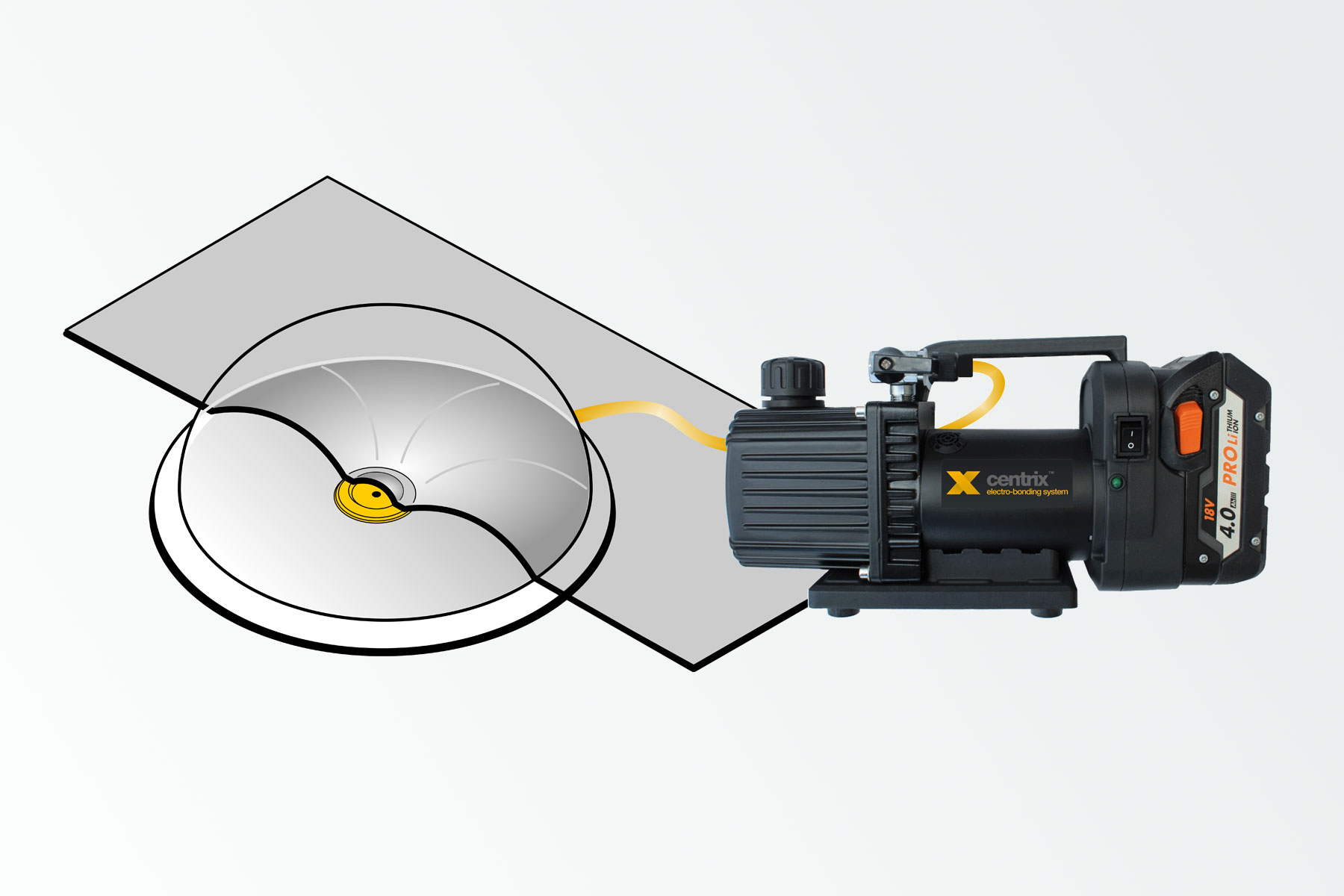

Safety and reliability are built in

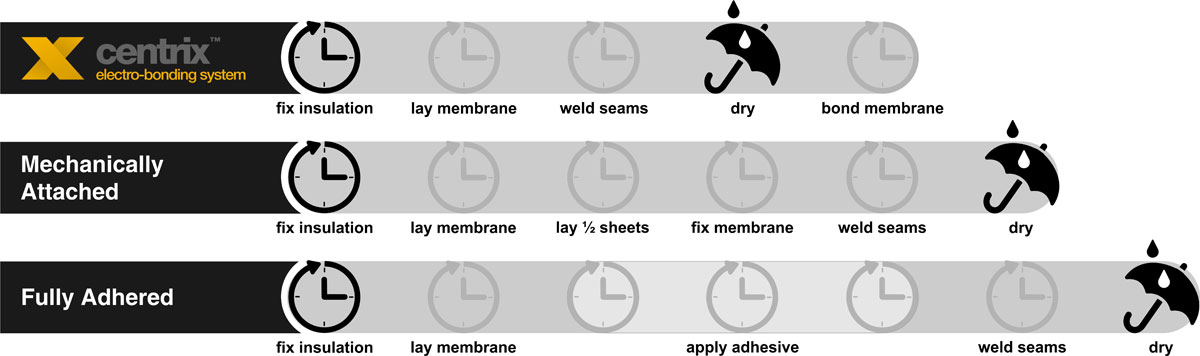

Our induction bonding technology is proven to be safe and reliable. And, unlike some other membrane attachment methods, it doesn’t use adhesives – so there are no fumes or unpleasant odours, and none of the chemicals that can affect projects at sensitive sites such as schools and hospitals.